Curating a product from the depth of your imagination and putting the same effort into bringing it to the real world is almost similar to a sheer miracle and is considered a neck-breaking action.

Once your organization cracks the deal regarding the latest innovative technology, it will start making a huge difference during the production process as well as the quality deliveries. With the initiation of AI, fabrication destinations such as the apparel and textile industry which were traditionally operated can easily reap numerous benefits.

Do you know that digital Technology assists in cost-cutting as well as elevating efficiency in time?

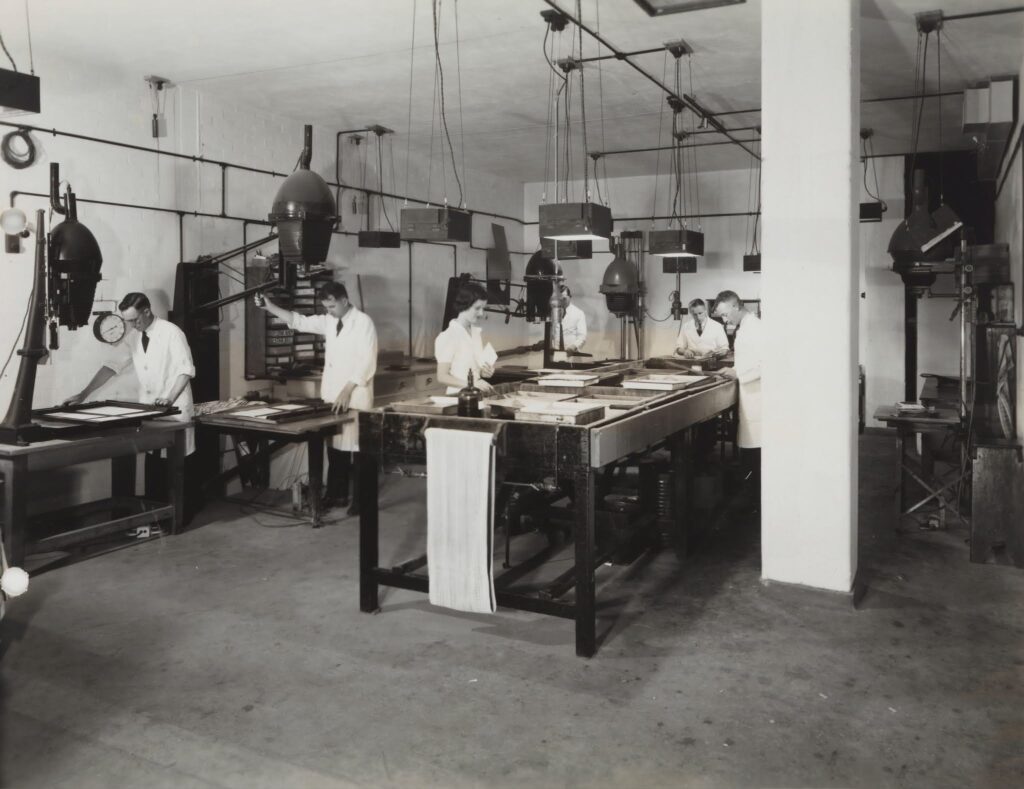

Evolution of Textile Machinery

Modern textile production equipment no longer necessitates the services of skilled workers. The computerization of textile production methods has allowed previously manual processes to be carried out in the clothing and textile industries.

Moreover, sustainability is a major issue for all sectors at the moment. As a result, there has been an uptick in demand for eco-friendly and wholesale fabrics among the general public. Many large companies are enthusiastic about continuing their work with sustainability-focused groups in order to create new, eco-friendly products.

As a result, it helps lessen landfill waste while also yielding water- and energy-efficient, biodegradable clothing with a long lifespan.

Growth of Digital Printing

In recent years, digital printing has become a crucial tool for the textile sector.

These digital printers make it simple for designers to create the best design possible, one that makes effective use of their many talents and abilities in the textile, printing, and fashion industries.

Due to their remarkable productivity, digital printers have emerged as the cutting-edge tool of choice in the textile industry. Revolutionizing production and design with their ability to cut down on costs and increase efficiency.

Journey of the textile Industry

With the help of nanotechnology, the textile industry can create clothes with a more futuristic aesthetic, including those that are fireproof, self-cleaning, and water-repellent.

Designs can be printed on fiber with greater speed and accuracy using laser printing technology.

Machines can now be used to create pleats, thanks to technological advancements.

Knitting machines create wide strips that are looped and stitched together to create knitted fabrics.

Thinner, more resilient fiber is required for 3D printing and the creation of novel products.

That’s true, right?

Professionals in the field have recently shown an interest in creating anti-theft technology to stop the exact replica production of priceless brand pieces.

As a result, companies are willing to put money into this sector of the textile industry. This is to help combat fraud, which is a major problem in the industry right now.

Looking Ahead

The textile industry has always prioritized the final product or deliverable. However, in today’s rapidly evolving technological landscape, businesspeople have taken an active interest in it. It began investing in the advancement and application of science and technology in the textile and apparel sectors.

Large sums of money invested and steady advancement in the field will eventually yield a better future with endless opportunities. This is to lower expenses and raise profits without sacrificing product quality or quantity.

However, modernization from automation might not be entirely an uphill task within the textile industry. Accordingly, there is a crucial requirement for such sectors in order to support the company. Also, put it into action prior to the dwindling of the whole industry. The amount of technology with respect to the automation of machinery manufactured has transformed with the indigenous efforts around technology manufactured within industries around the globe. The efforts in order to strengthen the indigenous efforts include substantial as well as sustained backups of the majorly manufactured machines in the supply chain.