In the world of fluid power systems, hydraulic hoses and pneumatic hoses play a vital role in transmitting power from one component to another. These hoses are used in various industries and applications, each serving a specific purpose. Understanding the differences between hydraulic and pneumatic hoses is essential for selecting the right hose for your specific needs.

Understanding Hydraulic and Pneumatic Hoses

Before diving into the differences, let’s take a closer look at what hydraulic and pneumatic hoses are. Starting with hydraulic hoses, these are specifically designed to carry hydraulic fluid to generate power. Hydraulic hoses are commonly used in heavy machinery, such as construction equipment and agricultural machinery.

Pneumatic hoses, on the other hand, are designed to transport compressed air or gases. These hoses are typically used in pneumatic tools, like air compressors and impact wrenches. They are also found in various industries where compressed air is required for powering machines or equipment.

Definition of Hydraulic Hose

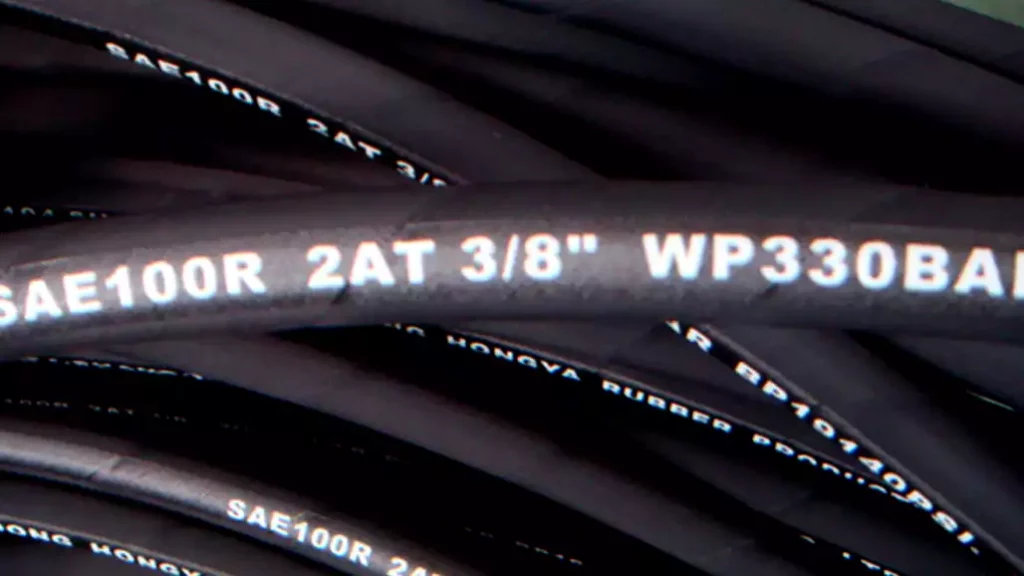

A hydraulic hose is a flexible tube specifically designed to carry hydraulic fluid under high pressure. It is typically made of synthetic rubber and is reinforced with several layers of braided or spiraled wires to withstand the high pressure.

Hydraulic hoses are crucial components in hydraulic systems, which are widely used in industries such as construction, mining, and agriculture. These hoses play a vital role in transmitting power from hydraulic pumps to various hydraulic cylinders or motors, allowing the machinery to perform a wide range of tasks efficiently.

The construction of hydraulic hoses involves careful engineering and selection of materials to ensure durability and reliability. The inner tube, made of synthetic rubber, is resistant to the hydraulic fluid being transported and can withstand high temperatures and pressure. The reinforcement layers, usually made of high-tensile steel wires, provide strength and prevent the hose from bursting under extreme pressure.

In addition to the inner tube and reinforcement layers, hydraulic hoses also have an outer cover that protects the hose from abrasion, chemicals, and environmental factors. The outer cover is typically made of synthetic rubber or thermoplastic, depending on the specific application requirements.

Hydraulic hoses come in various sizes and pressure ratings to accommodate different hydraulic systems. They are often color-coded for easy identification and are labeled with important information such as maximum working pressure, temperature range, and manufacturer’s specifications.

Definition of Pneumatic Hose

A pneumatic hose is a flexible tube designed to transport compressed air or gases. It is usually made of synthetic rubber, thermoplastic, or a combination of both, and may be reinforced with a mesh or textile braiding for added strength.

Pneumatic hoses are essential components in pneumatic systems, which rely on compressed air or gases to power various tools and equipment. These hoses enable the transfer of pressurized air from the air compressor to pneumatic devices, such as impact wrenches, nail guns, and pneumatic cylinders.

Similar to hydraulic hoses, the construction of pneumatic hoses involves careful selection of materials to ensure optimal performance. The inner tube, made of synthetic rubber or thermoplastic, is designed to withstand the pressure and temperature of the compressed air or gases being transported.

Depending on the specific application, pneumatic hoses may have reinforcement layers made of textile braiding or mesh. These layers provide additional strength and prevent the hose from expanding or bursting under high pressure.

Pneumatic hoses also have an outer cover, which is typically made of synthetic rubber or thermoplastic, to protect the hose from abrasion, chemicals, and environmental factors. The outer cover may have additional features such as oil resistance or flame retardance, depending on the intended use of the hose.

Like hydraulic hoses, pneumatic hoses come in various sizes and pressure ratings to accommodate different pneumatic systems. They are often color-coded for easy identification and may be labeled with information such as maximum working pressure, temperature range, and compliance with industry standards.

Key Differences Between Hydraulic and Pneumatic Hoses

While hydraulic and pneumatic hoses may appear similar at first glance, there are distinct differences that set them apart. These differences include the material composition, pressure handling capabilities, and temperature resistance.

When it comes to material composition, hydraulic hoses are primarily made of synthetic rubber, known for its durability and resistance to hydraulic fluids and oils. The reinforcement layers provide added strength and prevent the hose from expanding under high pressure. This composition ensures that hydraulic hoses can withstand the demanding conditions of hydraulic systems, making them a reliable choice for various applications.

On the other hand, pneumatic hoses can be made from synthetic rubber, thermoplastic, or a combination of both. The choice of material depends on the required flexibility, strength, and resistance to specific gases or chemicals. This versatility allows pneumatic hoses to be tailored to different pneumatic systems and their unique requirements.

When it comes to pressure handling capabilities, hydraulic hoses are designed to handle high-pressure applications. They have working pressures ranging from hundreds to thousands of pounds per square inch (PSI). This is because hydraulic systems generate significant forces that require robust hoses to contain and transmit the hydraulic fluid effectively. The construction of hydraulic hoses ensures that they can withstand the extreme forces generated by hydraulic systems, making them an essential component in industries such as construction, manufacturing, and agriculture.

Pneumatic hoses, although also capable of handling high pressures, typically have lower working pressures compared to hydraulic hoses. This is because pneumatic systems generate lower forces and require less pressure to function effectively. The lower working pressures of pneumatic hoses make them suitable for applications such as air tools, pneumatic cylinders, and air compressors.

When it comes to temperature resistance, hydraulic hoses are engineered to withstand a wide range of temperatures. They can operate in extreme cold as well as high heat, making them suitable for use in diverse environments and climates. This temperature resistance ensures that hydraulic hoses maintain their performance and reliability even in challenging conditions.

On the other hand, pneumatic hoses typically have a narrower temperature range, and their performance may be affected in extreme temperatures. It is important to choose the appropriate hose material based on the intended application and temperature conditions. Factors such as ambient temperature, proximity to heat sources, and exposure to extreme weather conditions should be considered when selecting pneumatic hoses.

In conclusion, while hydraulic and pneumatic hoses share similarities, such as their ability to transmit fluids and handle pressure, their differences in material composition, pressure handling capabilities, and temperature resistance make them suitable for distinct applications. Understanding these differences is crucial in selecting the right hose for specific systems and ensuring optimal performance and safety.

Common Uses of Hydraulic Hoses

Hydraulic hoses find widespread use in various industries and applications due to their ability to handle high pressures. Some common uses of hydraulic hoses include industrial and automotive applications.

Industrial Applications

In industrial settings, hydraulic hoses are used in machinery such as hydraulic presses, cranes, forklifts, and construction equipment. They enable the smooth operation of these heavy-duty machines, providing the necessary power for lifting, pushing, and moving heavy objects.

Automotive Applications

In the automotive industry, hydraulic hoses are used in steering systems, brakes, and suspension systems. They play a crucial role in transmitting hydraulic fluid to ensure smooth and precise control of the vehicle’s steering and braking mechanisms.

Common Uses of Pneumatic Hoses

Pneumatic hoses are widely used in industries that rely on compressed air or gases for various purposes, such as manufacturing and medical applications.

Manufacturing Applications

In manufacturing facilities, pneumatic hoses power pneumatic tools, air-operated machinery, and automated systems. They are commonly used for powering tools such as air drills, impact wrenches, and paint sprayers, increasing productivity and efficiency in the manufacturing process.

Medical Applications

In the medical field, pneumatic hoses are often used in medical devices and equipment, such as respiratory therapy devices, blood pressure monitors, and surgical instruments. These hoses ensure the safe and reliable transmission of compressed air or gases critical for various medical procedures and treatments.

Choosing Between Hydraulic and Pneumatic Hoses

When selecting between hydraulic and pneumatic hoses for your specific application, several factors should be considered to make an informed decision.

Factors to Consider

- Application Requirements: Consider the specific needs of your application, such as the required pressure, flow rate, and temperature range. Hydraulic hoses excel in high-pressure applications, while pneumatic hoses are suitable for lower-pressure applications.

- Environment: Evaluate the operating conditions of your application, including temperature extremes, exposure to chemicals or oils, and potential abrasion or impact. Choose a hose that offers the necessary resistance and durability to withstand these conditions.

- Cost and Maintenance: Consider the initial cost, as well as the ongoing maintenance and replacement costs of the hose. Hydraulic hoses generally require more frequent inspections and maintenance, while pneumatic hoses may have lower maintenance requirements.

- Availability: Ensure that the selected hose and its accessories are readily available in your region, minimizing downtime in case of hose replacement or repair.

- Expertise: If you are unsure about which hose to choose, consult with fluid power experts who can provide guidance and recommend the most suitable hose for your specific requirements.

Cost Implications

While cost is an important consideration, it should not be the sole determining factor. Choosing the right hose based on performance and compatibility with your application requirements will ensure efficiency, reliability, and long-term cost savings.

By understanding the differences between hydraulic and pneumatic hoses and considering your specific application needs, you can select a hose that maximizes performance, durability, and safety. Whether you require the power of hydraulics or the versatility of pneumatics, choosing the correct hose is crucial for the success of your fluid power system.